公司简介

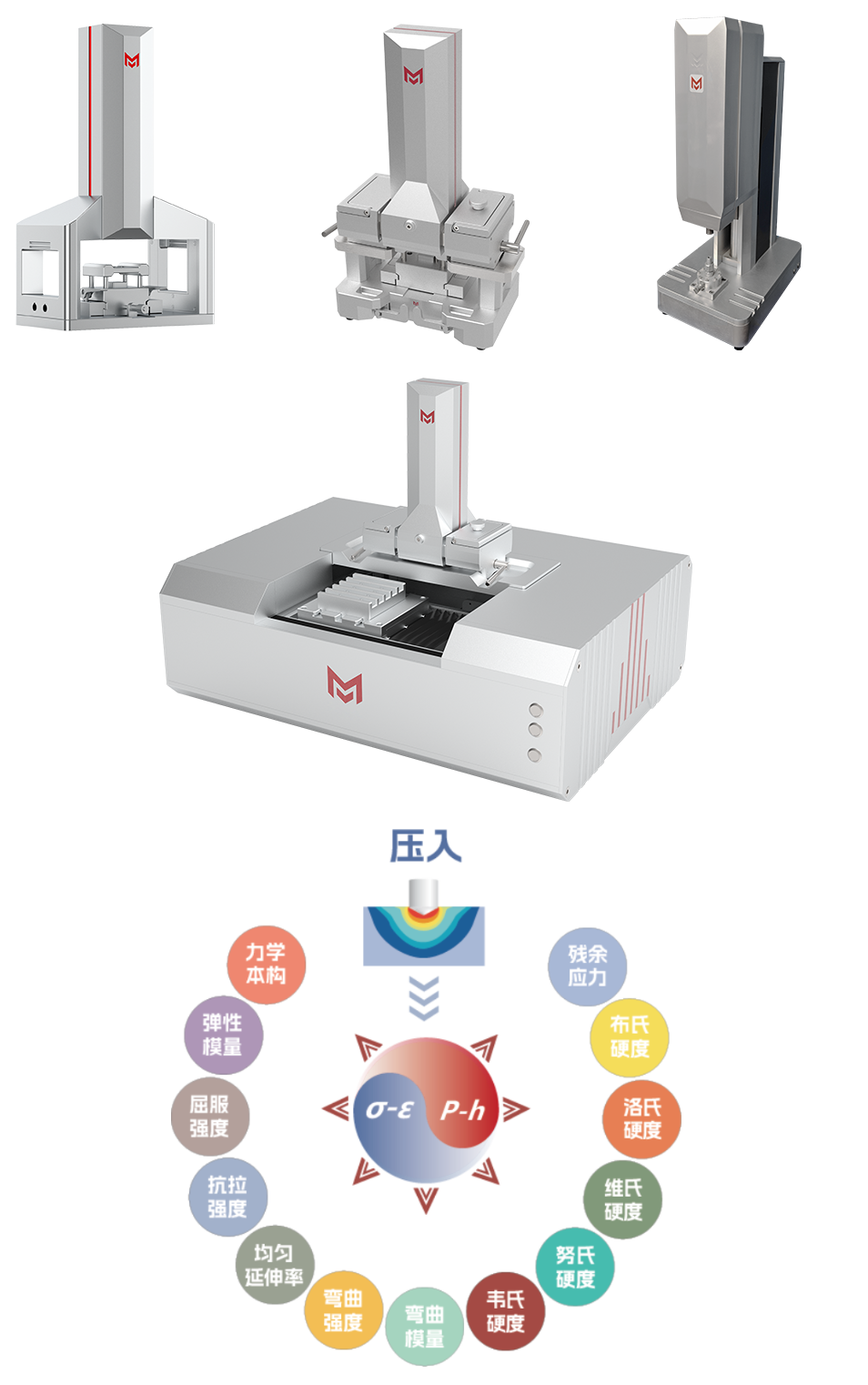

成都微力特斯科技有限公司(MMTI)是一家联合西南交通大学科研团队进行材料毫微测试技术开发与应用的高新技术企业。压入式力学试验与分析系统包括:MMTI-S(在役型压入仪)、 MMTI-R(微样型压入仪)、MMTI-SR(全能型压入仪)、MMTI-SR-XYA(双向自动压入系统)和MMTI-C构元仪产品是根据 C理论(能量密度等效理论)而研发的小型、便携设备。在毫微尺度、近似均质与各向同性的材料条件下,基于连续介质力学代表性体积单元的能量密度等效,可实现球、锥、平面压头和锥-锥、平面-锥与锥-平面单体压头对微试样或构件材料表面进行压入加载,及对小尺寸构元试样(如圆环、圆饼、圆球、SPT圆片)及对含裂纹试样(如CT、SEB等小试样)施加单向拉伸或压缩加载,通过测得的载荷位移曲线,实现材料宏观变形行为表征与材料的基础力学律与性能指标的获取。基于C理论的试验方法和压入式力学试验与分析系统仪器产品可以克服传统试验方法在不同环境下针对关键工程(如石油化工、核电、航空、高铁、特种设备等)结构服役材料、焊接接头以及小尺寸先进材料进行宏观弹塑性力学律精准测试面临的巨大困难,可测得材料的基础力学律:应力-应变关系,基础力学性能:弹性模量、屈服强度、抗拉强度、均匀延伸率、布氏(4种标尺)、洛氏(3种标尺)、维氏(1种标尺)、努氏硬度(1种标尺)等14种指标,特别是对于焊缝接头,在通过单个压点的复合压入试验精确测出残余应力的同时,还可测出包括力学律的一系列力学性能指标。

通过MMTI-SR-XYA双向自动压入系统,设备具备沿被测表面直线方向自动完成至少10个测点的连续压入能力,点间距可在0.5mm~2mm范围内精确设定,压入区间范围10mm~20mm。该自动化功能显著提高了测试效率,特别适用于焊接接头阵列压点压入及大批量试样的高通量测试需求。该功能既可用于实验室微小试样的精密压入测试,也完全兼容在役结构的现场检测应用。此外,针对增材制造等先进制造领域所制备的材料,该功能能够快速、系统地表征其力学性能空间分布,为新材料研发和工艺优化提供高效且可靠的评价手段。

通过MMTI-C构元仪,在对系列微试样测得上述指标之外,由裂纹试样(如CT、SEB)试验可测得材料断裂韧性;通过漏斗型小试样可测得材料低周疲劳Manson-Coffin律,进一步通过低循环能量密度等效换算可得材料疲劳裂纹扩展Paris律。

公司的首席科学家团队实现了包括弹塑性压入的一系列弹塑性问题的解析求解。提出和发明了基于圆锥、柱平面、锥-柱复合压头压入试验及小冲杆试验、圆环试验、断裂韧性试验的一系列先进材料试验方法,综合发表了70余篇高水准论文(JCR Q1论文33篇),获得授权发明专利20余项,其中包括微力特斯公司获得授权的5项国家发明专利及获得软件著作权1项。基于金属材料压入理论与试验方法,公司首席科学家主持制定了拥有中国自主知识产权的国家标准GB/T 37782-2019:《金属材料压入试验强度、硬度、应力应变关系测定》(中、英文)、GB/T 46428.1-2025《金属材料 板状、棒状微型试样 第1部分:疲劳试验方法》和中国团体试验标准:T/CSTM 00287-2021:《金属材料强度、应力应变关系的圆环压缩试验方法》。

Chengdu Miniature Mechanical Testing Science & Technology Co. Ltd. (MMTI) is a high-tech enterprise jointly developing and applying material nano-testing technologies in collaboration with the research team from Southwest Jiaotong University. The indentation mechanical testing and analysis systems—MMTI-S (In-service Indenter), MMTI-R (Micro-sample Indenter), MMTI-SR (All-round Indenter), MMTI-SR-XYA (Bi-directional Automatic Indentation System), and the MMTI-C Component Tester—are small, portable devices developed based on C Theory (Energy Density Equivalence Theory). Under nano-scale, approximately homogeneous and isotropic material conditions, and based on the energy density equivalence of the Representative Volume Element (RVE) in continuum mechanics, these systems enable indentation loading on the surfaces of micro-samples or component materials using spherical, conical, and planar indenters, as well as composite indenters (cone-cone, plane-cone, and cone-plane). They also apply uniaxial tensile or compressive loading to small-sized component specimens (e.g., rings, disks, spheres, SPT disks) and cracked specimens (e.g., CT, SEB). By measuring load-displacement curves, the systems achieve the characterization of macroscopic material deformation behavior and the acquisition of fundamental mechanical laws and performance indices. The testing methods and instrument products based on C Theory overcome the immense difficulties faced by traditional testing methods in accurately testing the macroscopic elastic-plastic mechanical laws of structural service materials, welded joints, and small-sized advanced materials in critical engineering projects (such as petrochemical, nuclear power, aviation, high-speed rail, special equipment, etc.) under different environments. They can measure the material's fundamental mechanical laws: stress-strain relationships, and fundamental mechanical properties: Elastic Modulus, Yield Strength, Tensile Strength, Uniform Elongation, Brinell (4 scales), Rockwell (3 scales), Vickers (1 scale), and Knoop Hardness (1 scale), totaling 14 indicators. particularly for welded joints, the systems can accurately measure residual stress through a composite indentation test at a single point while simultaneously determining a series of mechanical property indicators including mechanical laws.

Through the MMTI-SR-XYA Bi-directional Automatic Indentation System, the equipment possesses the capability to automatically complete continuous indentation on at least 10 measurement points along a linear direction on the tested surface, with point spacing precisely settable within the range of 0.5mm to 2mm, and an indentation range of 10mm to 20mm. This automated function significantly improves testing efficiency, making it particularly suitable for array indentation on welded joints and high-throughput testing demands for large batches of samples. This function is applicable to the precision indentation testing of tiny laboratory samples and is fully compatible with on-site inspection applications for in-service structures. Furthermore, for materials prepared in advanced manufacturing fields such as additive manufacturing, this function allows for the rapid and systematic characterization of the spatial distribution of mechanical properties, providing an efficient and reliable evaluation method for new material development and process optimization.

Through the MMTI-C Component Tester, in addition to measuring the aforementioned indicators on a series of micro-samples, material fracture toughness can be measured using cracked specimens (e.g., CT, SEB). Through funnel-shaped small specimens, the material's low-cycle fatigue Manson-Coffin law can be measured, and the material's fatigue crack propagation Paris law can be further obtained through low-cycle energy density equivalence conversion.

The company's chief scientist team has achieved analytical solutions for a series of elastic-plastic problems, including elastic-plastic indentation. They proposed and invented a series of advanced material testing methods based on conical, cylindrical-planar, and cone-cylinder composite indenter indentation tests, as well as small punch tests, ring tests, and fracture toughness tests. Collectively, they have published over 70 high-level papers (33 JCR Q1 papers) and obtained over 20 authorized invention patents, including 5 national invention patents authorized to MMTI and 1 software copyright. Based on the theory and testing methods of metal material indentation, the company's chief scientist presided over the formulation of the National Standard GB/T 37782-2019 with independent Chinese intellectual property rights: "Metallic materials—Determination of strength, hardness and stress-strain relationship by indentation" (Chinese and English versions), GB/T 46428.1-2025 "Metallic materials—Plate and rod micro-specimens—Part 1: Fatigue testing method," and the China Group Standard T/CSTM 00287-2021: "Standard Test Method for Compressive Testing of Metallic Rings to Determine Strength and Stress-Strain Relationship."